Essential Link Belt Forestry Tips for Efficient Timber Harvesting Techniques

In the dynamic field of timber harvesting, the integration of effective techniques and innovative methods is crucial for maximizing productivity and sustainability. Among these techniques, link belt forestry represents a strategic approach that enhances efficiency during timber extraction processes. By utilizing specialized equipment and adhering to best practices, forestry professionals can streamline operations while minimizing environmental impact.

This article delves into essential tips for implementing link belt forestry, offering insights into the latest advancements and techniques that can significantly improve harvesting outcomes. Whether you are an experienced forester or new to the industry, understanding the nuances of link belt forestry can lead to improved operational efficiency and better resource management. As we explore these tips, we will highlight the importance of safety, equipment maintenance, and the role of technology in optimizing timber harvesting practices.

Essential Overview of Link Belt Forestry in Timber Harvesting

Link Belt Forestry, an essential approach in timber harvesting, emphasizes the integration of advanced techniques and equipment for optimized operations. Understanding the fundamentals of Link Belt Forestry can significantly enhance the efficiency of timber harvesting processes. The primary focus lies on leveraging mechanized systems that streamline the entire operation, from felling the trees to transporting the harvested timber. This integration reduces labor costs and minimizes environmental impact, which is vital in today's eco-conscious marketplace.

At its core, Link Belt Forestry revolves around the proper assessment of timber resources and the implementation of sustainable practices. The technique involves planning the harvesting layout to maximize accessibility while preserving the surrounding ecosystem. Training workers in best practices for equipment use and safety is equally critical. This knowledge not only improves productivity but also ensures that the workforce is equipped to handle challenges encountered during the harvesting process. Implementing these fundamental principles results in a more efficient, cost-effective timber harvesting operation that aligns with environmental stewardship.

Key Techniques for Efficient Timber Felling and Processing

Timber harvesting is a critical process in forestry that requires careful planning and execution to ensure efficiency and sustainability. One of the key techniques for effective timber felling is to assess the area beforehand. Conducting a thorough evaluation allows you to identify the best trees to harvest while minimizing damage to surrounding vegetation. This not only promotes the health of the forest but also maximizes the quality of the timber collected.

Additionally, employing proper cutting techniques can greatly enhance the efficiency of timber processing. For instance, utilizing the directional felling method helps control the way trees fall, reducing the risk of injury and damage to adjacent trees. Another tip is to employ a systematic approach such as clear-cutting or selective cutting based on the goals of the operation. This tactical planning ensures that resources are used wisely and that the timber is harvested in a way that supports ecological balance.

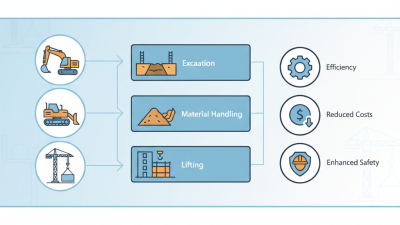

Lastly, efficiency can be improved by investing in suitable equipment for both felling and processing. Regular maintenance of tools and machinery is essential to avoid delays and ensure safety. The right equipment enhances productivity by allowing for faster processing times, reducing labor costs, and ultimately contributing to a more successful timber harvesting operation.

Safety Practices for Timber Harvesting Operations

Safety is paramount in timber harvesting operations, where the combination of heavy machinery and natural elements can pose numerous risks. Workers must be equipped with personal protective equipment (PPE) such as hard hats, gloves, and steel-toed boots to reduce the risk of injury. Additionally, high-visibility clothing allows for better visibility among crew members, especially in dense forest environments. Regular safety training and drills are crucial as they prepare workers to respond effectively to emergencies, ensuring that everyone on site is aware of potential hazards and knows the correct procedures to follow.

Incorporating safety practices into daily operations not only protects the workforce but also enhances overall productivity. Before commencing any operations, conducting thorough risk assessments helps identify specific dangers related to the site and the equipment being used. Proper equipment maintenance is essential; regular inspections can prevent mechanical failures that might lead to accidents. Furthermore, establishing clear communication among team members, whether through hand signals or radio communication, facilitates quick updates regarding any changes in conditions or potential hazards, thereby maintaining a safer work environment. By prioritizing safety measures, timber harvesting operations can achieve efficiency while minimizing risks to their staff.

Best Equipment and Tools for Link Belt Forestry

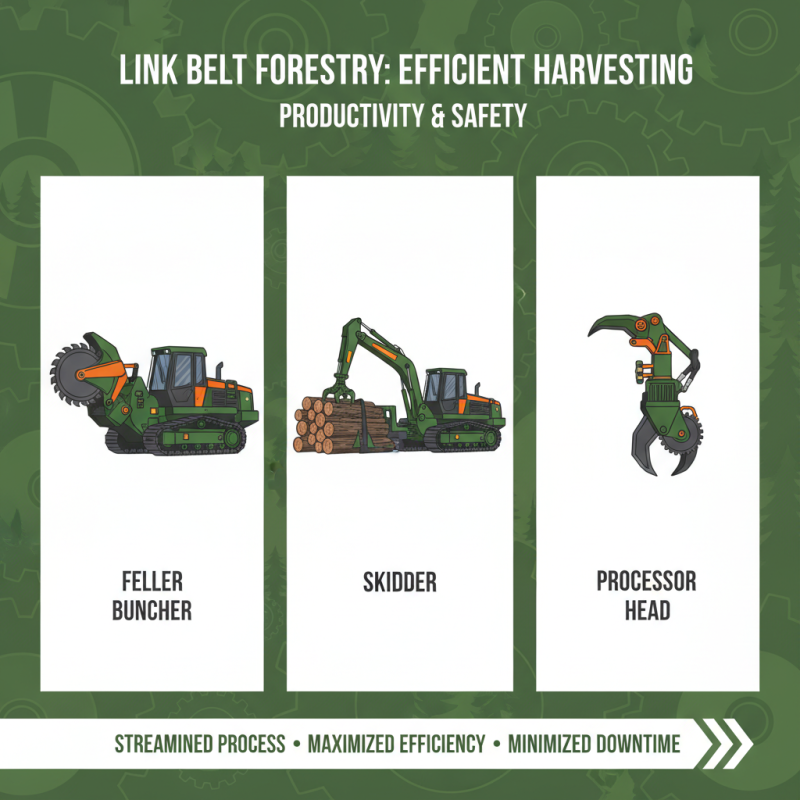

When it comes to efficient timber harvesting, selecting the right equipment and tools is paramount. In Link Belt forestry, productivity and safety go hand in hand. Key pieces of equipment such as feller bunchers, skidders, and processor heads are crucial in streamlining the harvesting process. These machines are designed to handle the rigors of forest environments, enabling operators to maximize efficiency while minimizing downtime.

To enhance your timber harvesting techniques, consider these essential tips: first, ensure that your equipment is well-maintained to avoid any mechanical failures during operation. Regular inspections can prevent costly repairs and ensure safety on-site. Second, invest in operator training to enhance skill sets. Knowledgeable operators can maneuver equipment effectively and safely, reducing the risk of accidents. Lastly, utilize advanced technologies such as tracking systems to monitor equipment performance and productivity, allowing for real-time adjustments and improved planning.

Equipping your forestry operations with the right tools also includes implementing safety gear and communication devices. Having proper personal protective equipment (PPE) for all team members fosters a safer working environment. Additionally, utilizing two-way radios can improve coordination and communication among team members, ensuring that everyone is aligned during the harvesting process. By focusing on both the right tools and best practices, your timber harvesting efforts can achieve maximum efficiency and safety.

Environmental Considerations in Timber Harvesting Practices

Timber harvesting, while essential for the forestry industry, poses significant environmental challenges that must be addressed to promote sustainable practices. According to the Food and Agriculture Organization (FAO), forests cover approximately 31% of the world’s land area but are increasingly threatened by unsustainable logging practices. Efficient timber harvesting techniques should prioritize minimal environmental impact, such as preserving biodiversity, maintaining soil quality, and ensuring water conservation.

The use of advanced harvesting technologies can greatly reduce the ecological footprint of timber extraction. Techniques such as selective logging and reduced-impact logging (RIL) minimize damage to surrounding trees and soil. A study published by the International Journal of Forestry Research highlighted that RIL can reduce soil disturbance by up to 70% compared to conventional methods. Moreover, implementing buffer zones around water bodies can protect aquatic ecosystems, with research indicating that maintaining these zones decreases water pollution by 54%. By integrating these environmentally conscious methods, the forestry sector can achieve a balance between economic viability and ecological stewardship, ensuring forests remain resilient for future generations.

Related Posts

-

Top 10 Link Belt Equipment Options for Your Construction Needs

-

How to Choose the Right Heavy Equipment for Your Construction Needs

-

Top 10 Tips for Buying High Quality Construction Used Equipment

-

Top Equipment Machines to Watch in 2025 for Increased Efficiency and Productivity

-

Why Investing in Modern Construction Equipment and Machinery is Essential for Your Success

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

Subscribe to our newsletter.