How to Choose the Right Link Belt Machine for Your Construction Needs

Choosing the right equipment for construction can significantly impact the efficiency and success of a project. Among the various types of machinery available, the link belt machine stands out for its versatility and robust performance in handling heavy lifting tasks. Whether you're working in excavation, material handling, or demolition, selecting the appropriate link belt machine tailored to your specific construction needs is essential to optimize productivity and ensure safety on the job site.

In this guide, we will explore the key factors to consider when choosing a link belt machine. From understanding the different models and their capacities to evaluating the specific requirements of your project, making an informed decision can lead to better outcomes. The right link belt machine not only enhances workflow but also contributes to maintaining a safe working environment, as it is designed to handle various loads efficiently and reliably. By carefully assessing your construction needs and understanding the capabilities of link belt machines, you can make a choice that aligns with both your operational goals and budget constraints.

Understanding Different Types of Link Belt Machines for Construction

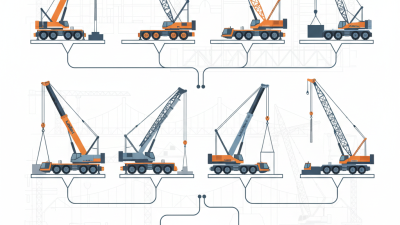

When selecting a Link Belt machine for construction, it’s essential to understand the specific types available and how they align with your project’s requirements. Two primary categories include excavators and cranes.

Excavators are versatile machines suited for digging, demolition, and material handling. They come in various sizes and configurations, from compact models ideal for urban sites to larger versions designed for heavy-duty tasks. Knowing the weight capacity and operational reach is crucial to ensure it meets the demands of your project.

Cranes, on the other hand, are designed for lifting and moving heavy loads across job sites. There are different types of cranes, such as tower cranes for tall structures, crawler cranes that offer stability on uneven terrain, and mobile cranes for flexibility and ease of transport. Each type has its advantages depending on the job site conditions and the specific lifting needs. By understanding the capabilities and limitations of these machines, you can better assess which Link Belt equipment will optimize your construction efficiency.

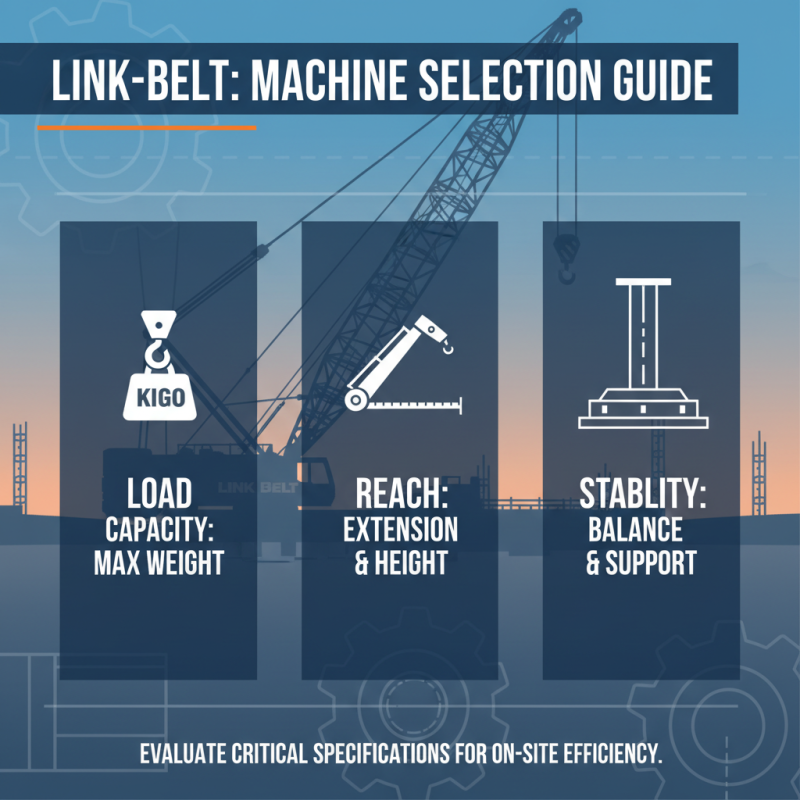

Evaluating Key Specifications: Load Capacity, Reach, and Stability

When selecting a Link Belt machine for construction, it's essential to evaluate critical specifications such as load capacity, reach, and stability. Load capacity dictates how much weight the machine can lift safely, making it a fundamental aspect of your selection process. Ensure that the machine you choose can handle the maximum weight you expect to encounter on-site, considering both the materials and potential combinations of loads.

Reach is another key factor to assess. It defines how far the machine can extend its arm or boom to access materials or perform tasks. Depending on the nature of your project, you may require a machine with an extensive reach to maneuver in tight spaces or across uneven terrain. Carefully analyze the specific dimensions and reach capabilities of different models to find the right fit for your job site.

**Tip:** Before making a decision, consult with operators or supervisors who have experience with similar machines. Their insights can provide valuable perspective on performance and usability.

Additionally, stability is paramount for safety and efficiency. A stable machine will ensure that heavy loads can be lifted safely without risk of tipping. Factors such as the machine's design, weight distribution, and base width affect stability. Always prioritize machines with features that enhance stability when selecting from various options.

**Tip:** Inspect the operating environment for potential stability issues—factors like slope, soil condition, and nearby structures can impact a machine's performance. Consider these elements carefully when evaluating your options.

Assessing Terrain and Job Site Requirements for Optimal Machine Selection

When selecting the right link belt machine for your construction needs, one of the most critical aspects to consider is the terrain and job site requirements. The type of ground you will be working on can significantly impact the performance and efficiency of your chosen machinery. For instance, soft, uneven, or muddy terrain may require machines with a wider footprint or better traction capabilities to prevent sinking or slippage. Assessing the soil conditions, slope, and overall site stability ensures that the machine can operate effectively without compromising safety or performance.

Additionally, understanding the specific requirements of the job site is essential for optimal machine selection. Factors such as the size of the site, the reach needed for operations, and clearance heights play a vital role in determining the most suitable equipment. If the location is confined or presents obstacles, compact and versatile machines may be the way to go. Conversely, for larger sites with expansive areas, machines with considerable power and lifting capacity may be more appropriate. By carefully evaluating these factors, construction professionals can choose a machine that aligns with both the terrain and the specific demands of the job, ultimately enhancing productivity and ensuring project success.

Choosing the Right Link Belt Machine for Various Terrain Types

Comparing Cost vs. Performance: Budgeting for Link Belt Equipment

When selecting the right equipment for construction needs, one of the most critical considerations is the balance between cost and performance. Budgeting for construction machinery often involves assessing not only the initial purchase price but also factors such as maintenance costs, fuel efficiency, and potential resale value. It's essential to evaluate how each machine's performance aligns with the specific tasks at hand. A lower upfront cost might save money initially, but if the equipment lacks the necessary features or reliability, it could lead to increased operational costs over time.

Moreover, understanding the scope and scale of your projects is vital in making a cost-effective decision. For instance, heavy-duty machinery may be necessary for large-scale operations, whereas lighter, more versatile options might suit smaller projects better. Analyzing the workload and the machine's specifications allows an informed choice that aligns performance with budget constraints. By taking the time to assess both current and future needs, construction managers can allocate their budgets more effectively, ensuring they invest in machinery that not only meets their immediate requirements but also enhances long-term productivity and efficiency.

Analyzing Industry Trends and Innovations in Link Belt Machinery

When it comes to selecting the right machinery for construction projects, understanding current industry trends and innovations is essential. Modern Link Belt machines have witnessed significant advancements designed to enhance productivity and efficiency. For instance, the integration of smart technology allows operators to monitor equipment performance in real-time, reducing downtime and maintenance costs. Innovations such as telematics systems enable construction firms to predict equipment failures before they occur, ensuring seamless project execution.

Tips: When assessing the latest in machinery technology, prioritize features that align with your project needs. Look for machines with user-friendly interfaces and robust data analytics capabilities to maximize operational efficiency.

Additionally, sustainability has become a pivotal focus in the construction industry. Many new Link Belt machines are designed with eco-friendly engines that comply with strict emission regulations, helping companies meet their environmental targets without compromising performance. Understanding these innovations can significantly influence your purchase decision, ensuring that you choose a machine that not only fits your immediate needs but also aligns with future construction practices.

Tips: Consider the long-term costs associated with fuel consumption and environmental regulations when selecting machinery. Investing in efficient, eco-friendly options can lead to substantial savings over time.

How to Choose the Right Link Belt Machine for Your Construction Needs

| Machine Type | Weight Class (Ton) | Max Load Capacity (Ton) | Engine Power (HP) | Key Features | Industry Trends |

|---|---|---|---|---|---|

| Excavator | 20 | 25 | 150 | Compact design, Advanced hydraulics | Increased automation, Eco-friendly models |

| Crawler Crane | 150 | 200 | 300 | High lifting capacity, Slew ring | Modular designs, Enhanced safety features |

| Truck-mounted Crane | 30 | 40 | 240 | Versatile Mobility, Quick setup | Hybrid technology, Real-time load monitoring |

| Backhoe Loader | 8 | 12 | 75 | Two-in-one functionality, Easy maneuverability | Growing demand for multi-functional equipment |

| Telehandler | 14 | 5 | 100 | Extendable boom, Enhanced visibility | Increased versatility, Demand in logistics and warehousing |

Related Posts

-

10 Essential Tips to Find the Best Link Belt Dealer Near You

-

Top Equipment Machines to Watch in 2025 for Increased Efficiency and Productivity

-

How to Choose the Right Heavy Equipment for Your Construction Needs

-

Top 10 Tips for Buying High Quality Construction Used Equipment

-

Top 10 Link Belt Crane Dealers You Should Consider for Your Next Project

-

Top 10 Link Belt Equipment Options for Your Construction Needs

Subscribe to our newsletter.